CLAUSTHAL UNIVERSITY OF TECHNOLOGY

Institute of Mineral and Waste Processing, Recycling and Circular Economy Systems (IFAD)

DATA & FACTS

Project

European Training Network for the remediation and reprocessing of sulfidic mining waste sites (2018 – 2022)

Scientific contact

Prof. Dr.-Ing. Daniel Goldmann

EU-Funding line

Horizon 2020

Projektleitung: Prof. Dr.-Ing. Arno Kwade

Projektname: „Li-Ion Pilot Lines Network“ (LiPLANET)

Keywords: Energie, Mobilität, Partner

SULTAN – Turning an “extractive-waste problem” into a “resource-recovery opportunity”

For more than 100 years, the mining industry in the EU has been disposing its mineral residues. If poorly managed, these residues pose a significant threat to the environment, but also contain valuable metals and recoverable minerals, e.g. gold, silver, cobalt, barite. This project, which is designed as a “European Training Network” (ETN), is to train young scientists in order to secure the raw materials supply in Europe. This is being carried out within the framework of the SULTAN project on the basis of the question of the extent to which mineral mining waste from sulfur-bearing deposits can be recycled and valuable raw materials extracted. Two former mines in the Erzgebirge and in Belgium and an active mine in Portugal serve as application cases. In total, 15 early stage researchers (ESRs) are supervised in the SULTAN project with the final goal of obtaining a doctorate and are prepared for their careers within and outside of science with interdisciplinary qualifications.

Research activities in SULTAN-project

The overall project includes the description of the residue depots, the development of treatment processes, the utilization of the recovered concentrates and a final overall assessment (Life Cycle Assessment).

Thus, SULTAN develops state-of-the-art methods for assessing the resource potential of the main tailings piles in Europe and researches environmentally friendly mining chemicals for advanced metal extraction/recovery systems. With the knowledge gained in SULTAN, not only the metals can be recovered, but also other clean residues can be used for the production of e.g. inorganic polymers, green cement or ceramics.

The Consortium

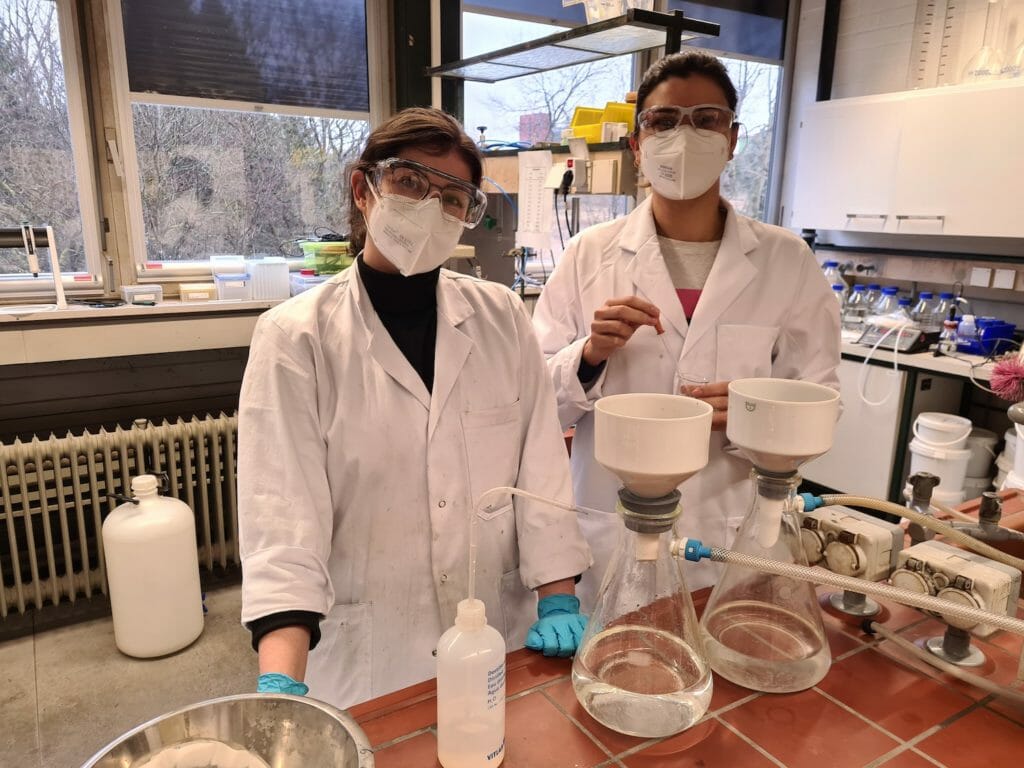

A total of eight funded partners and seven other partners from six EU countries plus Switzerland are active in the project. TU Clausthal is leading the largest sub-work package with seven ESRs, two of which are active at the Institute of Processing and supervised by Prof. Daniel Goldmann.

Project information This project is funded by the Horizon 2020-Programm of the European Commission and receives a total funding of 3,9 Mio. €; the duration of the action is 1.9.2018 till 31.8.2022 (GA# 812580).

Author:

Kai Rasenack

Date:

15.04.2022